In the process of software development, the procedures are often the same: first, the requirements are collected, then the system is designed, and finally, the code is written. Last but not the least is the crucial step of testing. This is all true for embedded solutions as well, but testing embedded systems is often a deeper, more complex process that focuses both on the hardware and software parts of the solution.

So, how exactly is embedded testing different from regular software testing? Why do we need to test embedded solutions in the first place, and how to build a process that delivers the necessary results? Find the answers to those questions and more in our guide to embedded system testing.

What Are Embedded Systems? Popular Examples of Embedded Solutions

Before we can delve deeper into testing embedded solutions, we need to first find out what embedded systems are and where they are used. The truth is that these systems have become so ubiquitous that there is a good chance you routinely interact with multiple embedded products daily without giving it much thought. There are numerous factors driving the growth of embedded technologies, from the surging demand for electric and hybrid vehicles to the increasing reliance on embedded healthcare systems that started back in the COVID-19 times.

Embedded systems are electronic devices in which software and hardware are paired to accomplish various tasks such as retrieving, processing, storing, and controlling data in variable electronics-based systems. They contain integrated computing mechanisms that are designed to perform those specific functions, and are often created for use in a particular industry or field. Here are the examples of embedded solutions available today.

Automotive control systems

Modern vehicles incorporate embedded technology for functions such as engine control, ABS (anti-lock braking), airbag deployment, and infotainment. These systems ensure vehicle safety, fuel efficiency, and driver assistance. They operate in real-time, often integrating with sensors, cameras, and communication networks to enhance performance and user experience.

Medical equipment

Pacemakers, insulin pumps, and MRI machines rely on embedded software to monitor and regulate critical functions with high precision. These systems ensure real-time responsiveness, accurate data processing, and seamless hardware and software integration with medical networks. They must comply with stringent regulations and operate reliably under various conditions to support patient health and safety.

Industrial automation

Factories and production facilities use embedded systems in robots, sensors, and control units to automate complex manufacturing processes. These systems handle real-time monitoring, precise motion control, and predictive maintenance. They enable higher efficiency, reduced operational costs, and improved product quality while ensuring seamless communication between various industrial machines and software platforms.

Smart home devices

Devices involving Internet of Things, such as smart thermostats, security cameras, and intelligent lighting systems, rely on embedded software for automation, remote control, and real-time decision-making. These systems integrate with mobile apps and cloud platforms to provide personalized user experiences, optimize energy consumption, and enhance home security with real-time monitoring and alerts.

Consumer electronics

Smartphones, gaming consoles, and wearable devices use embedded systems to manage performance, power consumption, connectivity, and user interfaces. These systems optimize battery life, support high-speed data processing, and enable seamless integration with other devices. Whether it’s an embedded system designed for entertainment, communication, or health tracking, it must ensure smooth operation and a high-quality user experience.

Don’t let hidden bugs derail your success

Top 7 Benefits of Embedded Testing

Determining whether the product is functional, usable, and able to perform well is essential for all solutions created today, and embedded systems are not an exception. If anything, both functional and non-functional testing of embedded solutions may be even more vital considering how many critical functions these products may have and how many essential tasks rely on them. These are the biggest reasons to do embedded testing.

1. Improved product reliability

Thorough embedded testing ensures that systems perform consistently under real-world conditions. Reliable products lead to fewer failures, reducing warranty claims, customer complaints, and costly post-release fixes, ultimately protecting a company’s brand reputation and maintaining customer trust in its offerings.

2. Faster time-to-market

By identifying and addressing issues early, embedded testing streamlines the development process, reducing delays caused by debugging and redesign. A faster release cycle allows companies to stay ahead of competitors, respond to market demands more efficiently, and capitalize on business opportunities without sacrificing product quality.

3. Compliance with industry standards

Many industries, such as automotive, healthcare, and aerospace, require strict conformance with regulatory and safety standards. Comprehensive testing helps ensure compliance, preventing costly certification failures, legal penalties, and the need for last-minute redesigns that could disrupt production timelines and increase expenses.

4. Reduced long-term maintenance costs

Well-tested embedded systems, even when they involve freshly created hardware or software, require fewer patches, emergency fixes, and support interventions after deployment. This minimizes operational disruptions, lowers maintenance costs, and allows companies to allocate resources more effectively, reducing the total cost of ownership over the product’s lifecycle.

5. Enhanced competitive advantage

High-quality, rigorously tested embedded systems differentiate a company from its competitors. A reputation for delivering dependable, well-functioning products can drive sales, strengthen customer loyalty, and open opportunities for expansion into new markets, giving businesses a strategic edge.

6. Risk mitigation for business operations

For companies that rely on embedded systems in their own operations — such as manufacturers, telecom providers, or logistics firms — testing ensures the system’s seamless functionality and consistent availability. Preventing system failures reduces the risk of downtime, inefficiencies, and financial losses caused by disrupted workflows or compromised service delivery.

7. Better vendor management and QA

Companies that outsource embedded system development to third-party manufacturers benefit from rigorous testing by ensuring the delivered products meet quality expectations. Independent verification reduces the risk of defective components entering production, strengthening supply chain reliability and ensuring consistent performance across multiple suppliers.

What Happens When Embedded Systems Go Untested?

The complexity of the systems and the hardware dependency makes embedded testing one of the more challenging testing activities performed by QA teams anywhere. At the same time, the consequences of not investing enough time and effort in testing embedded hardware and software can lead to a number of negative outcomes:

- System failures and downtime. Unreliable embedded systems can cause unexpected failures, leading to operational disruptions, production halts, or even complete system shutdowns.

- Safety risks. In industries like automotive, healthcare, and aerospace, malfunctioning embedded systems may pose serious risks to users, potentially causing accidents, injuries, or fatalities.

- Security vulnerabilities. Poorly tested embedded systems are more susceptible to cyber threats, including data breaches, unauthorized access, and malware attacks that can compromise sensitive information and critical operations.

- Regulatory non-compliance. Failure to meet industry standards and regulations can result in failed certifications, legal penalties, product recalls, and difficulties expanding to new markets due to increasingly complex global regulations.

- Integration and compatibility issues. Embedded systems often interact with other hardware and software components; inadequate testing can lead to compatibility issues, communication failures, or erratic behavior when deployed in real-world environments.

- Escalating costs of late-stage fixes. Software bugs and system performance issues discovered after deployment are significantly more expensive to fix than those caught early in development, leading to increased development costs and resource allocation.

- Customer dissatisfaction and brand damage. Unstable, glitchy, or unreliable products lead to negative customer experiences, poor reviews, loss of trust, and long-term damage to a company’s reputation and market position.

- Underperforming in growing competition. Companies with poorly operating embedded systems risk falling behind competitors who offer higher-quality, more reliable, and secure solutions, potentially losing market share and revenue.

Words by

Different Approaches and Methodologies to Embedded Testing

Testing an embedded system is a complex process that typically requires a different approach than the one used for testing regular software products. It goes without saying that the choice of testing methods and strategies will always depend on the specifics of the systems and the goals of the project. Here are the approaches and methodologies commonly used for embedded testing.

1. Black-box testing

This approach evaluates an embedded system’s functionality without examining its internal code or structure. Testers focus on inputs, expected outputs, and system behavior, ensuring compliance with requirements. It is ideal for validating user interactions, interfaces, and system-level functionality.

2. White-box testing

White-box testing examines the internal workings of embedded software, including code structure, logic, and data flow. Developers use techniques like unit testing and control flow analysis to detect logic errors, vulnerabilities, and inefficiencies in the codebase.

3. Gray-box testing

A hybrid of black-box and white-box testing, gray-box testing provides partial visibility into the system’s internal components. Testers analyze inputs and outputs while leveraging knowledge of system architecture to design more effective test cases, identifying integration issues and performance bottlenecks.

4. Manual testing

Testers manually execute test cases on embedded systems, validating real-world functionality, user interfaces, and hardware interactions. This approach is useful for exploratory testing, usability testing, and identifying issues that automated tests might miss.

5. Automated testing

Automation frameworks execute predefined test scripts, rapidly verifying system functionality, performance, and reliability. Automated testing is essential for regression testing, stress testing, and large-scale embedded system validation, improving efficiency and consistency.

6. Real-time testing

This approach ensures that an embedded system meets timing constraints and performs correctly under real-world conditions. As the name suggests, real-time operating system and device testing simulates real-time scenarios, such as sensor inputs and processing delays, to verify responsiveness and reliability in mission-critical applications.

7. Hardware-in-the-loop testing

HIL testing integrates embedded software with physical or simulated hardware components to test system behavior under real-world conditions. This method is widely used in automotive, aerospace, and industrial automation to validate control systems.

8. Fault injection testing

Fault injection testing involves introducing errors or failures, including power loss and sensor malfunctions, to evaluate how an embedded system responds to unexpected conditions. It helps assess fault tolerance, error recovery, and system robustness.

9. Test-driven development

TDD involves writing tests before the code to ensure that each piece of functionality is tested as it’s developed. This iterative approach is highly beneficial for embedded software development that produces reliable, high-quality products, especially in real-time or safety-critical applications, since it helps ensure that defects are caught early and reduces the risk of failures in production.

10. Behavior-driven development

BDD focuses on collaboration between developers, testers, and business stakeholders. It emphasizes clear communication through the use of simple, natural language to define system behavior. In embedded systems, BDD helps align functional requirements with tests that reflect how the system should behave, ensuring that the software meets the end user’s expectations while fostering better collaboration across teams. Together with TDD, BDD makes up a large part of Agile testing methodologies.

Accelerate development and streamline product success

Best Tools and Technologies for Embedded Software Testing in 2025

Embedded software testing requires not just in-depth knowledge of testing procedures and methodologies, as well as familiarity with the hardware-software connections used by embedded solutions, but also a firm grasp of tools, technologies, and programming languages used for this type of testing. Here is what embedded testers typically use in their work.

Programming languages for embedded testing

- C and C++. As the most common languages for embedded systems, C and C++ are widely used in testing, especially for unit and integration testing. Tools like CppUnit and Google Test provide automated testing capabilities for C++-based embedded applications.

- Python. Increasingly used for scripting, test automation, and hardware interaction, Python simplifies test case development and execution. Tools like PyTest, Robot Framework, and Behave (for BDD) are commonly used for automated embedded testing. Python is also useful for interfacing with hardware using libraries like PySerial for communication with microcontrollers.

Testing frameworks and tools

- VectorCAST. A powerful tool for unit and integration testing in safety-critical embedded applications, widely used in aerospace, automotive, and medical industries.

- Ceedling. A test framework for C-based embedded development, integrating with CMock for mocking dependencies.

- Google Test. A widely used framework for testing C++ applications, including embedded software.

- JTAG and in-circuit debuggers. Hardware tools like Segger J-Link and ARM Keil ULink allow for debugging and on-target testing directly on microcontrollers.

- Hardware-in-the-loop testing systems. Platforms like NI LabVIEW and dSPACE enable real-time simulation and hardware integration testing.

The Most Common Embedded Software Testing Types

Testing embedded devices is not limited to software: most strategies also incorporate testing their hardware components. There are different kinds of testing used for these solutions, and here are the ones that are often used in embedded testing.

Functional testing

A method used to verify that an embedded system performs according to its design specifications. This approach focuses on testing all features, user interactions, and expected outputs without analyzing internal code structure. Functional testing helps confirm that the system meets business and technical requirements under normal and edge-case conditions.

Usability testing

A testing technique that assesses how easily and efficiently users can interact with an embedded system’s interface. This process focuses on factors like navigation clarity, responsiveness, and user experience to ensure that operators, technicians, or consumers can use the system intuitively. Usability testing is essential for embedded devices with displays, touch controls, or complex input mechanisms, such as medical devices, automotive infotainment systems, and industrial control panels.

Unit testing

A testing approach that isolates and evaluates individual software modules or functions to identify defects early in development. By testing the smallest units of code separately, developers can ensure that each component performs as expected before integrating it with the rest of the system. Moreover, embedded unit testing is often automated to improve efficiency and accuracy.

Integration testing

Embedded software integration testing is a process that verifies how different software modules, hardware components, and external systems work together within an embedded environment. It identifies communication failures, data exchange issues, and incompatibilities that might not be apparent in isolated unit tests. Integration testing in embedded systems is crucial for ensuring seamless interaction between interconnected components.

System testing

A comprehensive evaluation of the embedded system as a whole to determine whether all hardware and software components function correctly together. This type of testing includes functional validation, system-level performance assessment, and compliance checks against user requirements. It is typically conducted after integration testing and before deployment.

Security testing

Security testing is a crucial step in identifying vulnerabilities that could expose the embedded system to cyber threats, unauthorized access, or data breaches. It includes techniques such as penetration testing, encryption verification, and authentication checks to ensure that the system remains protected against potential attacks. Industries like automotive, healthcare, and IoT require stringent security measures.

Performance testing

A testing approach that evaluates an embedded system’s responsiveness, stability, and efficiency under varying conditions. Key aspects include execution speed, resource consumption, and system throughput. Performance testing ensures that the system operates smoothly, even in high-load scenarios or under strict real-time constraints.

Reliability testing

A long-term evaluation process that assesses how well an embedded system withstands extended usage and varying environmental conditions, such as temperature fluctuations, humidity, and power instability. Reliability testing is critical for applications where system failure could lead to operational downtime, financial losses, or safety hazards.

Compliance testing

A regulatory verification process that ensures an embedded system meets industry-specific standards, legal requirements, and certification guidelines such as ISO, IEC, FDA, HIPAA, and automotive safety regulations. Compliance testing is necessary for obtaining product approvals, avoiding legal penalties, and ensuring market readiness.

Embedded Software Testing Procedure: 10 Steps to Success

We have mentioned earlier that embedded system testing is a complex task that often involves focusing not just on the embedded software components, but also on the hardware elements and the way they interact with each other. This is why the process of testing embedded solutions does not always match the process of testing regular software. At the same time, the testing process for an embedded product is not that different from testing software:

- The software receives specific input data.

- A selected portion of the code is executed.

- The system’s behavior and state are monitored.

- The output is evaluated against requirements and expected results.

At the same time, the team must make sure the system does not crash and operates faultlessly under any conditions. So, how exactly do we get there? Here are the steps you need to take when testing embedded devices and software.

1. Define testing requirements and objectives

A clear understanding of system specifications, functional requirements, and performance expectations is essential before testing begins. This step involves gathering technical documentation, identifying key use cases, and defining success criteria. It ensures that testing aligns with business goals and regulatory standards, reducing the risk of gaps in validation.

2. Select appropriate testing approaches

Different types of embedded testing, such as functional, security, performance, and hardware-in-the-loop testing, must be chosen based on system complexity and application domain. The selection process considers factors like real-time constraints, safety requirements, and integration needs to ensure a comprehensive validation strategy.

3. Set up the test environment

The test environment must accurately replicate real-world conditions, including hardware components, software configurations, and external interfaces. This step may involve using simulators, emulators, physical prototypes, or hardware-in-the-loop setups to create an environment where embedded system behavior can be effectively analyzed.

4. Develop test cases and test scripts

Well-structured test cases outline expected inputs, outputs, and execution conditions. For automated testing, scripts are developed using testing frameworks that allow repeatability and efficiency. Test cases should cover normal operations, edge cases, and failure scenarios to ensure all system behaviors are validated.

5. Execute tests and record results

Tests are performed in a controlled manner, monitoring system responses and capturing detailed logs of any deviations from expected behavior. This phase includes manual testing, automated script execution, stress testing, and fault injection to evaluate the system’s stability and performance under different conditions.

We have tested 300+ products over 2+ decades — Find out what we can do for you

6. Analyze test results and identify defects

Test logs and reports are reviewed to identify defects, performance bottlenecks, or security vulnerabilities. Root cause analysis is performed to understand failure patterns and determine corrective actions. Any issues detected are documented and prioritized based on severity and impact.

7. Debug and fix issues

Detected defects are assigned to developers for resolution, followed by retesting to ensure fixes do not introduce new problems. Iterative debugging is critical for refining embedded systems, especially in safety-critical applications where reliability is a top priority.

8. Conduct regression testing

Once fixes and modifications are implemented, regression testing verifies that no new defects have been introduced and that previous functionality remains intact. Automated test suites help streamline this process, making it efficient and repeatable.

9. Perform compliance and certification testing

If the embedded system must meet industry-specific standards, compliance testing is conducted to validate adherence to relevant regulatory requirements (for example, ISO, IEC, or FDA standards). In certain industries, certification authorities may be involved in verifying system safety, reliability, and interoperability before product release.

10. Final validation and checking deployment readiness

The final tests are usually system-level and designed to ensure that the embedded system meets all functional, performance, and security requirements. Once the system passes validation, it is prepared for deployment, with test reports and documentation finalized for future reference and maintenance.

Automated Testing of Embedded Systems

At first glance, automated testing embedded systems seems difficult to achieve: when there are not just software, but also hardware components, automation can indeed prove to be challenging. At the same time, automated embedded testing is not only possible but also increasingly essential for ensuring the reliability and performance of embedded systems.

Pairing manual and automated testing for maximum efficiency

Unlike traditional manual testing, which can be time-consuming and error-prone, automated testing uses scripts, tools, and frameworks to execute tests repeatedly, improving efficiency, accuracy, and coverage in embedded software validation.

Automated embedded testing significantly complements manual testing by enhancing test coverage and allowing repetitive execution of test cases. While manual testing is still vital for certain aspects, such as usability or exploratory testing, automation is ideal for tasks like regression testing, unit testing, and performance testing.

Automated tests can be run continuously throughout the development cycle, ensuring early identification of defects and accelerating the feedback loop. Automation also reduces human error, improves consistency, and allows for testing in environments that would be impractical to replicate manually.

Automated testing for an e-learning platform: An in-depth case study

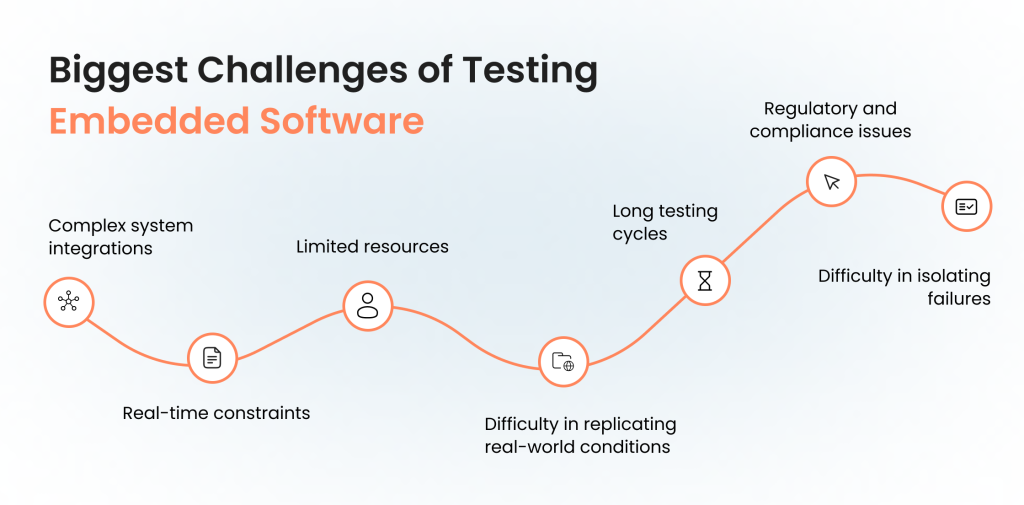

Biggest Challenges of Testing Embedded Software

There are many things that can make bug identification difficult even in regular software, not to mention the intricate, multi-layer embedded devices. When testing these systems, teams often encounter both typical and unique challenges. These are the most common challenges of embedded system testing.

Complex system integrations

Embedded units involve both software and hardware working in close synchronization, making testing more complex. Failing to properly test this integration can lead to significant issues in real-world performance.

Real-time constraints

Many embedded systems, especially in industries like aerospace or medical devices, have strict real-time requirements. Ensuring the system responds within milliseconds is critical. Testing real-time systems can be challenging because delays in software execution or sensor data processing can lead to system failures. For instance, in medical devices like pacemakers, failing to meet real-time requirements could be life-threatening.

Limited resources

Embedded systems often run on hardware with limited processing power, memory, and storage. This means that testing must consider resource constraints. For example, testing a smart thermostat might require simulating user interactions while keeping an eye on memory usage and CPU cycles, which all require extra input from a team whose resources may already be strained. If tests are not optimized, they could overwhelm the system, causing inaccurate results.

Difficulty in replicating real-world conditions

It can be challenging to create an environment that closely mimics real-world conditions. For example, testing an embedded system in a drone involves replicating factors like wind, temperature, and GPS signal variability. Failure to accurately replicate these conditions can lead to inaccurate test results and system failures when deployed in the field.

Long testing cycles

Testing embedded systems often takes longer due to the complexity of the systems, the need for specialized equipment, regular software updates that come with increased test coverage, and the difficulty in simulating real-world conditions. This is particularly true for industries like automotive or medical devices, where systems must undergo extensive safety and compliance testing and testing can span months or even years to meet regulatory requirements.

Difficulty in isolating failures

When failures occur, identifying the root cause can be difficult because issues could stem from either the hardware or the software. For example, in industrial automation systems, if a sensor fails to communicate properly with the controller, it can be hard to pinpoint whether the issue is in the sensor hardware, the communication protocol, or the software.

Regulatory and compliance issues

Embedded solutions are often subject to strict regulatory standards, especially in industries like healthcare, automotive, or aerospace. Ensuring the system meets these requirements during testing can be a big challenge. For instance, medical devices like insulin pumps must comply with FDA regulations, requiring extensive documentation and validation processes to prove safety and reliability.

Final Thoughts

The reliance on the hardware environment makes embedded testing a rather challenging task compared to regular quality assurance. Still, testing is the only feasible way to provide and guarantee functionality, stable performance, security in software solutions and applications for aviation, healthcare, transportation, and more. That’s why it’s crucial to implement embedded testing to improve software and hardware performance, reduce risks to both users and companies that utilize embedded systems in their equipment, as well as to bring down the costs of software development and maintenance.

Jump to section

Hand over your project to the pros.

Let’s talk about how we can give your project the push it needs to succeed!