Assembly testing is applied in PCB and electronic manufacturing. It’s aimed to verify if several modules, otherwise known as units, can communicate and produce the anticipated outcomes. Answering the question of what is assembly testing, it’s vital to say it ensures that no trivially observable malfunction occurs when parts of the system run.

Units are never isolated, so their activities are interconnected, and the output of one module can often be utilized as an input to another one. That’s why the related modules must be properly connected, stably interact, and provide the functional results as initially specified.

So, assembly testing is also known as Integration testing, and it’s a critical cross-check, able to save time and means for a manufacturer.

Why Is Assembly Testing Important?

When assembling a product from multifaceted materials and units, you should make sure they can properly integrate and interact. Thus, assembly testing helps to check how different materials and components react when combined.

This aspect is important to form an accurate project budget. When studying new materials, their qualities, and performance, you can always choose the unit, that meets your project needs and requirements best of all.

Assembly testing, thus, not only provides the standard results to various industries but also facilitates utilization of new products and materials. By the way, it’s used both by original and contract manufacturers, but, for sure, independent assembly testing is the best and the most trustworthy way to get unbiased results.

Testing assemblies is an ideal solution to uncover the root cause of a device failure because such testing allows to identify dependency mismatches, catch mistakes and syntax errors, detect environment incompatibilities, and much more. Thus, these tests are suitable for industries manufacturing complex products that require high accuracy.

Assembly tests are widely used in the aerospace and defense sector, medical, electronic, and optical equipment manufacturing, and much more.

How Is Testing Assembly Realized?

When speaking about assembly testing, we should mention that it’s often black-box testing, meaning a special app evaluates if a product properly responds to elementary input and then closes the program back.

A desktop application, for instance, would be tested through a specific tool built to check the app’s source code from a repository. After creating it, the binaries should be deployed on a testing machine and executed. The test would then simply ensure that the app opens a window and can close it again without error messages in the log file.

A web application would also require having the source code checked out from its repository, and then a specific tool built and deployed to a web server. The URL under which the app is running would then be accessed by the assembly test that will look for HTML marks, verifying that the app tested is running properly without error messages in the server/application logs.

What Are the Key Benefits of Assembly Testing?

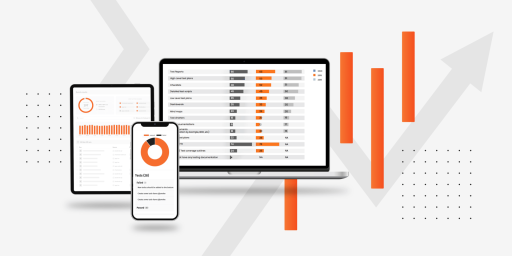

Assembly testing offers a number of benefits to those who want to verify a product, save time and catch about 30% of bugs at a stroke. To list a few:

Minimal effort to realize

It’s your continuous integration server that creates and deploys an application in a test environment. The only task of an assembly test is to invoke some important function, make sure it plausibly responds to the input without errors in the log files and then shut down.

Even though testing assemblies won’t completely verify technical or functional aspects, many of the characteristics would be touched, such as

- Databases and schemes,

- Binary dependencies,

- HTTP,

- External services,

- Log files,

- Bootstrap configuration and some more.

One per application

Since testing assembly does not head for precise results, it does not require fixing bugs or updates with new features. The function that matters is usually just one, so rarely would anybody require more than one assembly test per application.

Little attention on part of the developer

Assembly tests should not become a part of the developer’s daily routine. After a test has been created, it does not require showing up anywhere but for the app’s breakdown.

Built chain verification

At present, the tech stack is constantly expanding, and the programming languages are dynamic as well as run-time linking. That’s why a successful compilation can not at all guarantee the application will successfully run. Assembly testing, however, can verify the faultless operation and resiliency of the chain built quite effectively. Compiler, configuration, dependency resolution, deployment, and target runtime environment can be verified in the process of testing assemblies.

Configuration verification

Lots of things can go wrong nowadays because of the frameworks with dependency injection. Such things as URL spelling mistakes in JavaScript libraries, wrong database credentials, syntax errors in bootstrapping XML files, and more, can pass unnoticed during testing by other means and methods. For instance, unit tests are concerned with separate units in isolation, while integration testing is realized in simulated and simplified environments where configurations don’t apply.

Assembly testing, in its turn, runs in a real environment and includes its configuration in the functional verification.

Untested Assemblies Risks

Defective products can cause costly consequences for the manufacturer:

- The need to cover product/device/equipment warranty claims for repair or replacement. Any of the precedents may sensibly increase company monetary losses, which would not have happened if the defective merchandise were without defects.

- Detecting the root cause of the merchandising failure in the process of manufacturing can result in significant time and labor investments if done without proper testing.

- Additional costs for additional quality assurance before device/equipment distribution in the market.

- Loss of customer trust and loyalty, and consequently market share.

Final Thoughts

In a highly competitive world, manufacturing defective products entails costly consequences. With the advance in technology, there is also more demand for testing.

That’s why, to stay competitive and save time and money, you should consider assembly testing as a workable and cost-effective means to produce high-quality products. It plays already a crucial role in many industries. Assembly testing can be beneficial not only to your business but also to your brand reputation, which is highly valued in the modern world.